Measuring for Replacement Forks

It is a legal requirement to replace your forks. This is to make sure that your operation remains safe and complies with health and safety best practices. It can be a perplexing and time-consuming job to complete, so make sure to read until the end to become a master at choosing the right forks for your fleet.

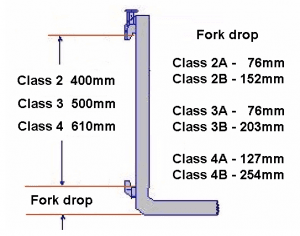

Forks are mounted to a forklift on a carriage which is used to attach the forks to the machine securely, they are split into several classes as follows:

Class 2: 400mm

Class 3: 500mm

Class 4: 610mm

The above measurements are common on the majority of all industrial forklifts and are widely used within the industry which allows for ease of identifying and picking the correct forks.

The height of the truck’s carriage will identify the class and is measured from the top of the lower hook to the bottom of the upper hook.

The fork drop is measured from the top of the lower hook to the floor. These two measurements together will determine the forks you require for your forklift.

For example, if my carriage height is 610mm and my fork drop is 127mm, I would require Class 4A forks. Using these two measurements will help you to identify which class of forks you require, this information is usually required by fork suppliers. To see which class you need please refer to the diagram below.

You should always check your forks for signs of wear on a regular basis. As soon as the original nominal thickness of the fork is reduced by 10%, they MUST be replaced (as per ISO 5057). 10% wear on a forklift fork means a reduction of the load-bearing capacity of approx. 20% – regardless of the forks supplier. This is for ITA FEM Hook forks which are the most commonly used. To explore the ranges of forks available please click here. Our online shop Liftruck UK have developed an Easy Order Form to help you with your fork sizes. We really hope this guide was helpful for you.