Forklifts are designed to handle heavy loads with efficiency, yet their stability is not as straightforward as it might appear. Unlike cars or trucks, forklifts have a very different balance system that makes them prone to tipping if used incorrectly. The concept that explains this balance is the forklift stability triangle. Once you understand how this triangular zone works, the reasons behind common accidents make far more sense, and the steps needed to prevent them become clearer.

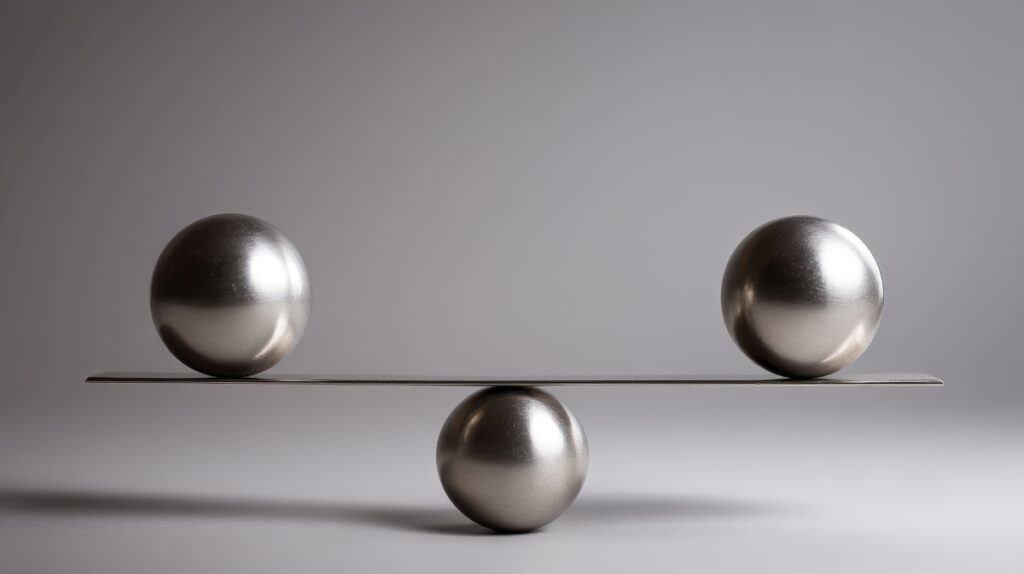

The stability triangle is a theoretical model that shows how a forklift maintains balance. Imagine drawing a triangle between the two front wheels and the pivot point of the rear axle. This triangular base acts as the forklift’s foundation. As long as the combined centre of gravity for the truck and its load stays within this triangle, the machine remains upright. If the centre of gravity moves outside the triangle, the forklift becomes unstable and may tip over. This simple idea underpins all safe forklift operation, yet it is often overlooked during day-to-day tasks.

Adding a load to the forks immediately shifts the balance. The heavier and higher the load, the more the centre of gravity moves towards the front axle. If the operator lifts a load too high, tiltes incorrectly, or positions it unevenly, the centre may move close to the triangle’s edge, creating instability. Turning sharply with a raised load is particularly dangerous because centrifugal force pushes the centre of gravity outward, sometimes past the triangle’s limits. Correct stacking, lifting with care, and keeping loads low while travelling are therefore not just good habits but essential safety practices.

Two main types of instability occur with forklifts: lateral tipping and longitudinal tipping. Lateral tipping happens when the machine overturns sideways, often caused by cornering too quickly or driving across uneven ground. Longitudinal tipping occurs when the forklift tips forward or backward, usually the result of overloading or lifting a pallet too high. Both situations trace back to the stability triangle being breached. Recognising how easily this can occur helps operators adjust their driving style and avoid complacency in routine tasks.

Every forklift comes with a capacity plate showing the maximum load it can safely lift at specific load centres and lift heights.. Exceeding these limits moves the centre of gravity dangerously close to the triangle’s edge. Even if the machine feels stable, it may already be at its tipping threshold. This is where understanding forklift capacity deration becomes vital. Deration refers to the reduction in rated lifting capacity as the load centre increases or the load is raised higher.. Many accidents happen because operators misjudge this reduction, assuming the rated capacity applies in all situations.

The working environment also plays a major role in how the stability triangle functions in practice. Driving on slopes, uneven surfaces, or wet floors changes how the centre of gravity shifts. A forklift that is stable on flat ground can become unstable on a ramp, especially when carrying a full load. Similarly, potholes, debris, or unexpected bumps can jolt the centre of gravity beyond safe limits. Warehouses and yards should therefore be designed and maintained with forklift stability in mind. Clear markings, well-kept floors, and designated travel routes reduce the likelihood of accidents.

Even with the right equipment and a well-maintained site, human behaviour often makes the difference between safety and danger. Operators who rush, take corners too quickly, or raise loads unnecessarily create conditions where the stability triangle is compromised. Fatigue, distraction, and overconfidence also contribute to mistakes. Regular refresher training, realistic productivity targets, and a workplace culture that prioritises safety over speed all help reduce these risks. Stability is as much about consistent habits as it is about technical design.

For employers, the stability triangle is more than just a training diagram. It represents liability, costs, and reputation. Forklift accidents caused by tipping often result in expensive damage to goods and equipment, not to mention serious injuries. Insurance claims and downtime add further financial burdens. By ensuring operators understand this concept, businesses not only protect staff but also improve efficiency. A stable forklift is a productive forklift, and safe practices almost always translate into long-term cost savings.

The most practical way to keep forklifts stable is to always travel with loads kept low, move at controlled speeds, and avoid sharp turns. Operators should never exceed rated capacities and should check capacity plates before handling unfamiliar loads. Employers should provide clear signage about maximum ramp gradients and install mirrors or cameras to aid visibility. Daily pre-use checks of tyres, brakes, hydraulics, and steering ensure the machine itself is not contributing to instability. Finally, investing in ongoing operator training ensures that the stability triangle is not just a theory learned once but a principle applied every day.

The forklift stability triangle may sound like a theoretical model, but in reality, it is the difference between safe operation and serious accidents. By keeping the combined centre of gravity within this triangular base, operators ensure that the machine remains stable and performs as intended. Employers who reinforce this principle through training, site design, and maintenance create safer and more efficient workplaces.

At Acclaim Handling, we not only supply forklifts but also support companies with training and hire services tailored to their needs. Whether you’re purchasing equipment outright or hiring forklifts for short-term logistics, understanding how the stability triangle works is one of the most important steps towards safer operations.