Manual handling moves goods slowly. A worker carrying boxes achieves perhaps 20-30 movements per hour, limited by human strength, stamina, and the simple physics of what one person can safely lift and transport.

A competent forklift operator handling the same goods moves hundreds of units in the same timeframe. The productivity multiplier isn’t marginal – it’s transformational. This fundamental capacity to move more material faster forms the foundation of modern warehousing and logistics.

Yet many operations fail to realise the full efficiency potential of their forklift fleets. Equipment sits idle while operators wait for work allocation. Poorly planned movements create unnecessary travel. Inadequate maintenance causes breakdowns that halt operations. The gap between theoretical capacity and actual performance represents substantial lost productivity.

Understanding how forklifts contribute to efficiency enables organisations to maximise returns on their material handling investment.

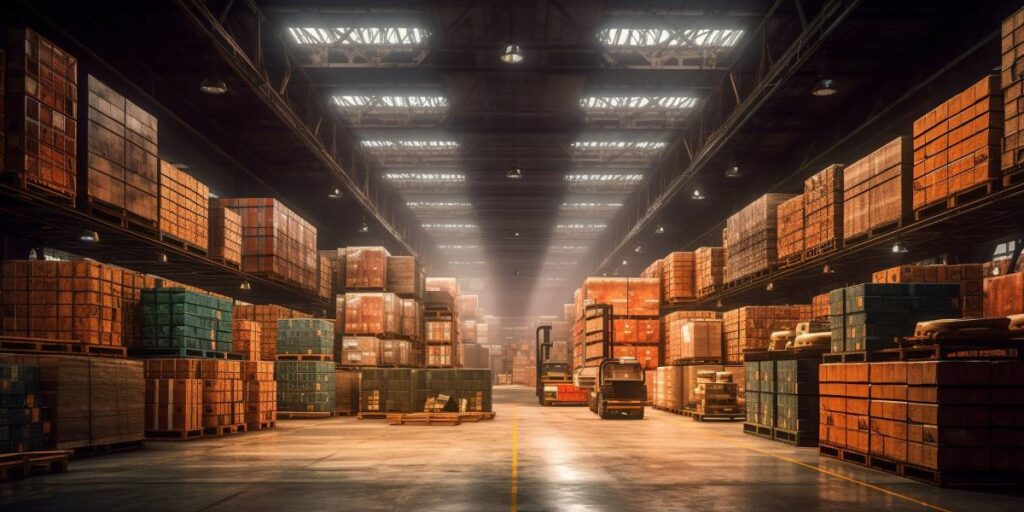

Warehouse space costs money. Ground-level storage is the least efficient use of that expensive asset.

Forklifts enable vertical storage by allowing safe placement and retrieval of goods at heights impossible through manual handling. Racking systems extending three, four, or five levels high multiply storage capacity within the same floor footprint.

This vertical utilisation transforms warehouse economics. A facility that can store four times the inventory within existing space avoids the capital cost of expanding or leasing additional warehousing. The cost of forklifts and racking infrastructure is substantially lower than acquiring more property.

Different forklift types optimise for different vertical storage approaches. Reach trucks access narrow aisles and extended heights efficiently. Counterbalance forklifts handle heavier loads to moderate heights. Order pickers enable staff to access high-level inventory for picking operations. Matching equipment to storage strategy maximises space utilisation.

The productivity gain compounds through reduced travel distances. High-density storage means more inventory within shorter reach, reducing the distance operators travel between storage and dispatch areas. This translates directly to more movements completed per shift.

Forklifts move loads faster than any manual method while maintaining safety and control.

An operator transporting a pallet across a warehouse completes the journey in a fraction of the time required for manual transport of equivalent goods. When this time saving applies across hundreds of movements daily, the cumulative productivity improvement is substantial.

Speed advantages extend beyond simple travel velocity. Forklifts accelerate and decelerate smoothly under load, whereas manual handlers must move cautiously with heavy items. Loading and unloading operations that might take several workers considerable time can be completed by a single operator in minutes.

This speed enables responsive operations. Goods arriving at the loading dock can be moved immediately to storage or cross-docked to outbound vehicles without lengthy handling delays. Customer orders can be picked, staged, and loaded rapidly, supporting same-day dispatch requirements that manual operations couldn’t achieve.

However, speed must be balanced against safety. Operators exceeding safe speeds in congested areas or around corners create hazards that ultimately reduce productivity through incidents and damage. Optimal efficiency comes from sustained appropriate speed rather than reckless haste followed by accident-related downtime.

Forklifts handle loads that would require multiple manual trips or several workers simultaneously.

A standard pallet might contain goods weighing 500-1000kg. Moving this manually requires breaking it down into individual items, transporting them separately, then reconsolidating. A forklift moves it as a single unit, eliminating the handling time and reducing damage risk from excessive touching.

This consolidation capability enables efficient storage and transport systems. Goods can remain palletised from receipt through storage to dispatch, minimising handling touchpoints. Reduced handling decreases damage rates while dramatically improving throughput.

The productivity multiplication becomes particularly apparent in high-volume operations. A distribution centre processing thousands of pallets daily simply couldn’t function without mechanical handling. The labour requirement for equivalent manual operations would be economically prohibitive even if physically possible.

Consolidation also enables standardised handling. Palletised loads have predictable dimensions and handling requirements, allowing optimised storage layouts and systematic picking procedures. This standardisation supports process efficiency that manual handling of varied individual items cannot achieve.

Workplace injuries reduce productivity through absenteeism, reduced capacity of injured workers, and the disruption caused when experienced staff are temporarily unavailable.

Manual handling injuries – particularly back injuries from lifting and carrying heavy items – represent a significant proportion of workplace incidents in warehousing and logistics. These injuries often result in extended absence and sometimes permanent work restrictions.

Forklift operations eliminate most manual handling of heavy items. Operators remain seated or standing on the machine, using mechanical power rather than physical exertion to move loads. The reduction in manual handling translates directly to reduced injury rates.

This has productivity implications beyond avoiding absence. Workers not subjected to constant heavy lifting maintain better long-term health and can sustain productivity throughout their careers. Older workers can continue in roles that would become physically impossible if dependent on manual handling.

The safety improvement also affects recruitment and retention. Roles involving heavy manual handling are increasingly difficult to fill as labour markets tighten. Mechanised operations that minimise physical demands access broader labour pools and experience lower turnover.

Forklifts support warehouse processes that would be impractical with manual handling.

Cross-docking operations – where incoming goods are immediately transferred to outbound vehicles with minimal or no storage – require rapid movement of full pallets between loading docks. Manual handling couldn’t achieve the speed necessary for effective cross-docking.

Just-in-time inventory systems depend on frequent small deliveries and rapid put-away. Forklifts enable the quick response times these systems require. Without mechanical handling, organisations would need to maintain larger buffer stocks, increasing working capital requirements and storage costs.

Reducing warehouse congestion through slotting – allocating storage locations based on pick frequency and product characteristics – becomes practical with forklifts. High-volume items can be positioned for optimal access, while slower-moving inventory occupies less convenient locations. Manual operations lack the flexibility to exploit such optimisation because moving goods becomes the limiting constraint.

Returns processing, quality control workflows, and cycle counting all benefit from the ability to rapidly relocate inventory as needed. Forklifts provide the movement capacity that allows warehouses to function as dynamic systems rather than static storage.

Modern warehouses handle diverse products with varying handling requirements. Forklifts equipped with appropriate attachments adapt to different needs without requiring completely different handling systems.

Clamp attachments handle appliances or other non-palletised loads. Rotators enable safe handling of items that need orientation changes. Fork positioners adjust to varied pallet widths. This attachment versatility means a single base machine can perform multiple handling tasks rather than requiring dedicated equipment for each application.

The flexibility extends to temporary capacity requirements. Seasonal peaks in many industries require substantially increased handling capacity for limited periods. On-demand equipment to support warehouse operations provides this capacity without the capital commitment of purchasing equipment that will be underutilised most of the year.

Different forklift types suit different applications within the same facility. Reach trucks for narrow-aisle high-density storage. Counterbalance forklifts for outdoor loading operations. Pallet trucks for horizontal movement within picking areas. Using appropriate equipment for each task optimises productivity across all operations.

Forklift operations generate measurable performance data that supports continuous improvement.

Movements per hour, utilisation rates, fuel consumption, and maintenance requirements provide visibility into operational efficiency. Modern telematics systems capture this data automatically, enabling analysis that identifies improvement opportunities.

An operation discovering that forklifts spend 30% of operating time travelling empty can redesign workflows to reduce unproductive travel. Analysis showing certain operators consistently achieve higher productivity can inform training to bring all operators to best-practice performance levels.

This data-driven approach to efficiency improvement is only possible with mechanised handling. Manual operations lack comparable metrics and visibility, making systematic optimisation difficult.

Fleet sizing decisions benefit from utilisation data. Operations might discover they’re overstaffed with equipment that sits idle substantial portions of shifts, or conversely that insufficient capacity creates bottlenecks during peak periods. Evidence-based fleet management optimises the balance between capacity and capital efficiency.

Forklifts increasingly integrate with warehouse management systems and other technologies that further enhance productivity.

Directed picking systems guide operators to optimal pick locations and sequences, eliminating navigation decisions that slow operations. Integration with inventory systems ensures operators always work from accurate location data, reducing time wasted searching for misplaced stock.

RFID and barcode scanning integrated with forklifts enable real-time inventory updates as goods are moved. This maintains system accuracy without requiring separate data entry, improving both efficiency and inventory visibility.

Automated guided vehicles and semi-autonomous forklifts represent the evolution toward fully automated material handling. While these technologies aren’t appropriate for all operations, they demonstrate how forklift capabilities continue expanding to support ever-greater efficiency.

Many operations achieve only a fraction of the productivity improvement forklifts could deliver because they haven’t optimised the surrounding systems and processes.

Poor warehouse layout forces excessive travel distances. Inadequate maintenance causes breakdowns and reduced equipment availability. Insufficient operator training results in slower, less efficient operation. Lack of work planning leads to reactive rather than optimised movement sequences.

Maximising forklift contribution to efficiency requires a systems approach. The equipment itself is necessary but not sufficient. Layout, processes, maintenance, training, and planning all need optimisation to realise full productivity potential.

Organisations that treat forklift investment as part of broader operational improvement rather than simply as equipment acquisition tend to achieve substantially better results. The productivity gains from well-deployed forklifts in optimised operations far exceed those from simply replacing manual handling without addressing the broader operational context.